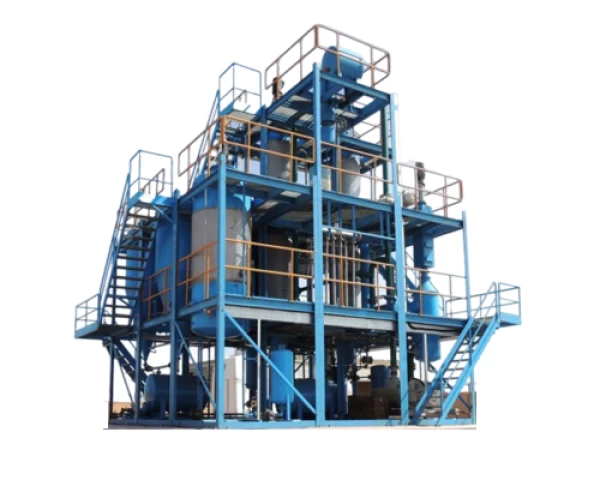

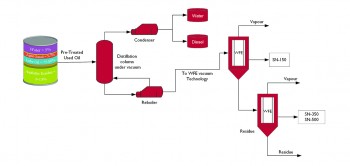

Used oil re-refining plant

Company name

:

Model

:

Price

:

Packaging

:

Minimum order

:

Negotiable

Standard

:

Production power

:

Negotiable

Payment type

:

Full Advance Payment

Post type

:

Negotiable

Description

: